Manufacturing Processes

Our Casting Capabilities by Process

Gravity Die Casting

Permanent mold casting with steel molds for medium volume production

Part Weight Range

1kg - 50kgMin. EAU

2,000 - 15,000 unitsTotal Machines

6 MachinesMachine Types

Horizontal, Vertical & HALL PM2x Horizontal PM Machines

27" - 34" X 20" - 50"

Ideal for medium to large parts with horizontal parting lines

3x Vertical PM Machines

22" - 30" X 22" - 35"

Optimal for parts requiring vertical mold orientation and precise filling

1x Horizontal HALL PM Machine

36" X 38"

Large-format capability for oversized parts and complex assemblies

Key Advantages

- Superior mechanical properties and surface finish

- Excellent dimensional accuracy and repeatability

- Cost-effective for medium to high production volumes

- Minimal post-casting machining required

- Reduced porosity compared to other casting methods

Typical Applications:

Automotive components, industrial parts requiring high strength and dimensional accuracy, heat sinks, housings, and structural components

Sand Casting

Green sand, low volume production

Part Weight

1 - 10 kgAnnual Volume

300 - 2,000 units

Air Set Casting

For niche low volume production

Part Weight

10 - 200 kgAnnual Volume

300 - 2,000 units

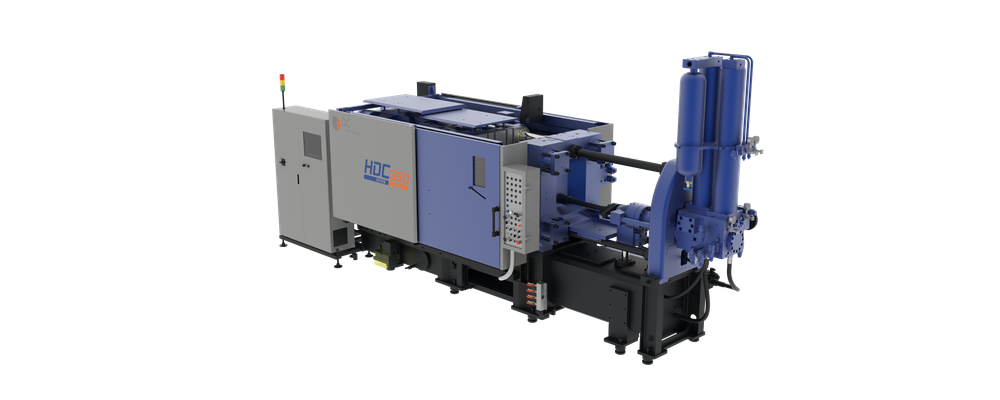

High Pressure Die Casting

State-of-the-art HPDC technology for high-volume production

Total Machines

2 HAITIAN HDC MachinesInjection Volume

1.5kg - 7.2kgClamping Force

3,500 - 5,500 kNProduction Type

High Volume Precision Parts1x HAITIAN HDC Series 550T

5,500 kN

1,200 x 1,200 mm

4.3kg - 7.2kg

1,375 cm²

Large-format high-pressure die casting for complex thin-walled components

1x HAITIAN HDC Series 350T

3,500 kN

910 x 910 mm

1.5kg - 3.0kg

875 cm²

Precision HPDC for medium-sized components with tight tolerances